why choose us

Why everyone likes Dawning so much

- FACTORY01Located in Shandong Province, Linyi City, near Qingdao port. Factory wholesale price, largest discount can be offered. There is no limited order qty for most products

- CUSTOMIZATION02Your logo, your package printing, your color decal designs all can be customized. We try our best to meet your demands. Currently, as for the auto-darkening welding helmets, we have more than 20 different color decal models for your choice.

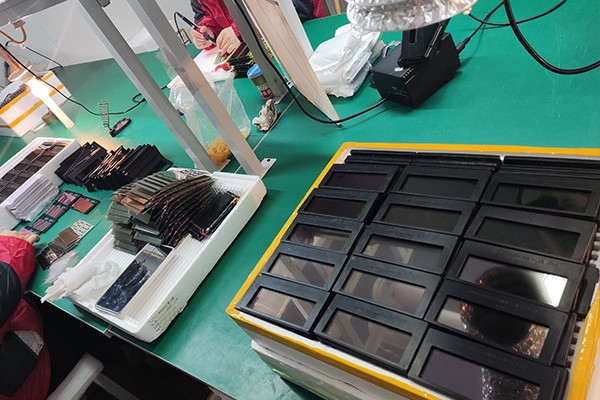

- QUALITY03We have our own specialised quality-control team. There will be a strict quality control, loading pictures or videos before every delivery.

- DELIVERY04We accept flexible delivery ways,LCL, direct delivery to your assigned warehouse and whole container. And prompt delivery time can be guaranteed.

news

With strong technical force, super cost-effective products and first-class marketing after-sales servic

-

How to adjust the dimming welding mask and what to pay attention to when using the automatic dimmingHow to adjust the dimming welding mask? What should I pay attention to when using an auto-darkening welding mask? The automat...2022-09-19READ MORE

-

Briefly describe the function and characteristics of labor protection productsDefinition of labor protection productsLabor protection equipment is an indispensable auxiliary measure to protect the safety...2022-09-19READ MORE

-

Use of automatic darkening welding mask and replacement of accessoriesAuto-darkening welding mask is a new type of eye protection, which is an auxiliary tool in the welding process. Compared with...2022-09-19READ MORE

-

Is the automatic dimming welding shield easy to use?The advantage of the auto-darkening welding helmet is to free up both hands, so that the left hand holding the welding helmet...2022-09-19READ MORE

Our factory covers 3,000 square meter and we have a professional team.There are many kinds of auto-darkening welding helmets with big view.Different decals can be customized to show customers’ uniqueness.We also produce portable plastic face shields with steel mesh visor and plastic visors which can be used in different working area.Visor color can be chosen,such as transparent,black,gray,brown,dark green.Copyright © 2022 Linyi Yonglei Labor Protection Supplies Co., Ltd | TECHNICAL SUPPORT | YUNSU NETWORK -